central dust collector for sale Smooth surface, not easy to produce burrs, small deformation. Using the latter method, the production rate is low, the surface is rough and easy to deform. In addition, there are plastic frames, but this frame is not suitable for use at high temperatures. In the spray process, because the filter bag is cleaned once, it will rub with the outer surface of the dust removal frame once, so the dust removal filter bag is used to the corresponding time, although it is not damaged, but its inner surface and the contact part of the dust removal frame have been worn, and the original part can be staggered according to the wear traces when reloading to avoid continuing to wear in the original place, which can extend the service life of the dust removal filter bag. central dust collector for sale is a kind of filter dust removal equipment with a wide range of use areas, mainly used to isolate solid impurities and gases, to filter and improve air quality. This kind of equipment is used in various chemical enterprises, and it is also very common in civilian households. The reason why it becomes a cloth bag is because the filter medium of this dust removal equipment is generally processed by fabric, and some also use non-woven fabrics.

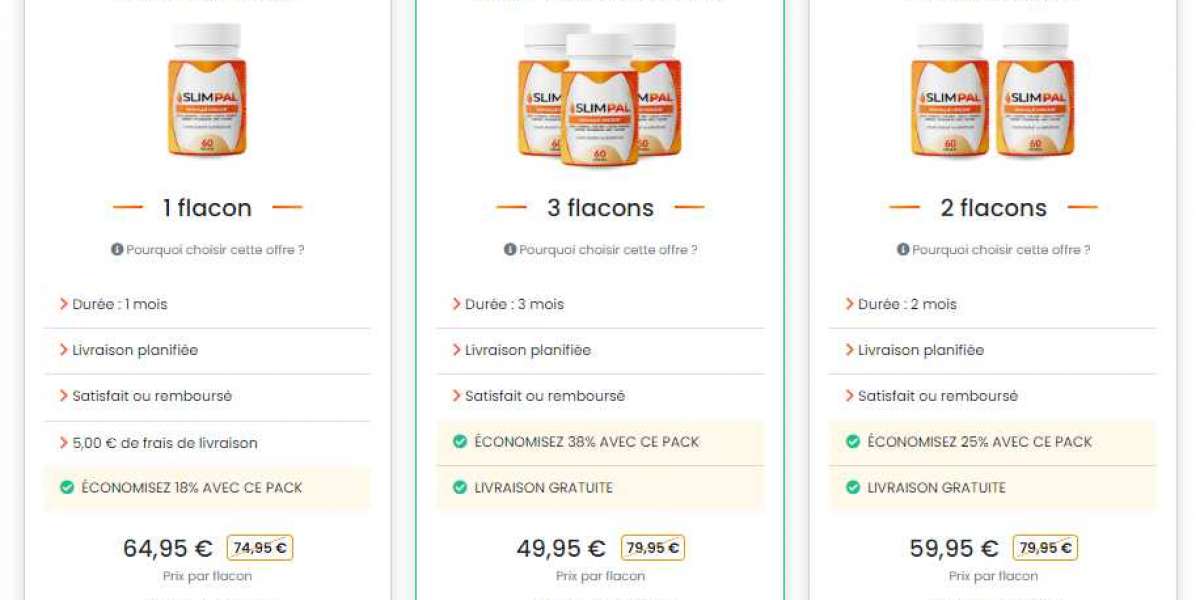

What is the process for selecting a central dust collector for sale? Below, for your detailed answer:

(1) The dust collector is selected according to the local conditions and the level of operation and management of the unit, and the type of dust collector is selected later in combination with the above situation. In general, for the selection of dust collector, if the above requirements can be met, the correct equipment selection can be made; For some special processes and special requirements, the problem is complex, and it is necessary to combine various comprehensive factors for comparative analysis, and then carry out a better design.

(2) Determining the resistance of the dust collector in the design of the dust collector, some special circumstances should be considered, such as the pressure balance of the system, the impact of rainy weather on the pulse central dust collector for sale, and the change of the long-term resistance of the dust collector.

(3) Technical and economic comparison: Analyze the technical and economic indicators of the pre-selected precipitator (there may be more than two kinds of precipitators that can meet the process requirements), and comprehensively consider the relevant factors such as equipment costs, operating costs, applicable years, and land area, so as to provide a basis for determining the dust collector later.

(4) Pre-selection: According to the basic factors considered, such as the physical and chemical properties of dust, purification requirements, and the scope of application of various dust collectors, the dust removal equipment is pre-selected.

(5) Environmental benefit analysis: determine the dust collector for all environmental benefit analysis. The dust removal effect is good, the gas emission concentration is low, not only brings benefits to the environment, but also brings benefits to production and life, the choice of equipment can not be ignored.

central dust collector for sale A branch lift valve is closed, the filter air is cut off, and then the electromagnetic pulse valve is opened, the compressed air expands in the upper box in a short time, and rushes into the filter bag, so that the filter bag expands and deforms to produce vibration, and under the action of reverse airflow. Dust attached to the outer surface of the filter bag is stripped and dropped into the ash hopper. Because its shell often has air leakage, so that the bag room gas temperature is lower than the dew point, the filter bag will be damp, resulting in dust is not loose, but sticky attached to the filter bag, the fabric hole blocked, resulting in ash failure, so that the dust collector pressure drop is too large, can not continue to run, some produce paste bag can not dust. After the cleaning is completed, the electromagnetic pulse valve is closed, the lifting valve is opened, and the chamber is restored to the filtering state. Cleaning each chamber in turn, from the beginning of room cleaning to the next cleaning for a cleaning cycle. The dust trapped by the filtration and ash cleaning work falls into the ash hopper, and then is centrally discharged by the ash discharging device at the mouth of the ash hopper.

central dust collector for sale https://www.kaisenfilter.com/Central-Dust-Collector