In today's world, where innovation meets convenience, home appliances have become an integral part of our lives. Behind the sleek and functional designs of these appliances lies the craftsmanship of Plastic Injection Mould Manufacturers. These unsung heroes play a pivotal role in shaping the appliances that make our daily routines smoother and more efficient.

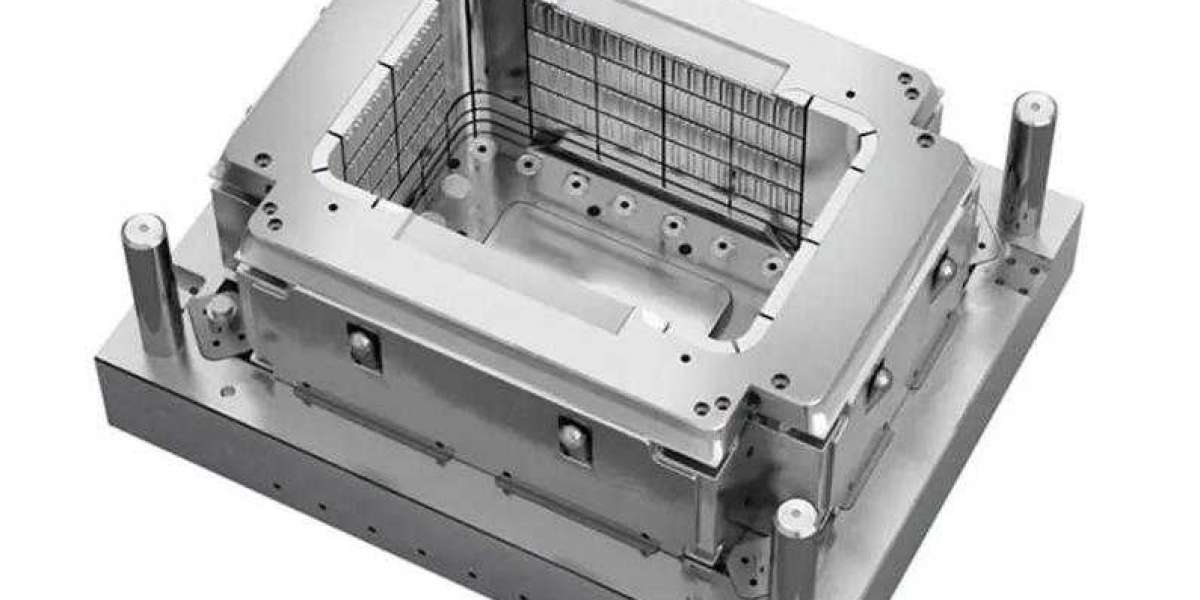

Plastic injection mould manufacturers are the creative minds and skilled hands behind the scenes. They are the ones responsible for producing the intricate moulds that give shape to the plastic components of our beloved home appliances. From refrigerators and washing machines to coffee makers and toasters, plastic injection moulds are at the heart of these devices.

One of the primary reasons why plastic injection moulds are so widely used in the home appliance industry is their versatility. They can mold plastic into virtually any shape, allowing designers and engineers to bring their innovative concepts to life. This flexibility in design is what makes modern home appliances not only functional but also aesthetically pleasing.

These manufacturers are also experts in choosing the right materials for the job. They consider factors such as durability, heat resistance, and cost-effectiveness when selecting plastics for specific appliance components. For example, the plastic used for the exterior of a coffee maker must be both heat-resistant and visually appealing, while the plastic used for internal components may prioritize durability and cost-efficiency.

Precision is the name of the game in this industry. The moulds produced by these manufacturers must be incredibly precise to ensure that every plastic component fits perfectly within the appliance. Even the slightest deviation in size or shape can lead to malfunctions, so precision and quality control are paramount.

Home Appliance Plastic Injection Mould Manufacturers are also highly attuned to the principles of sustainability. With increasing awareness of environmental concerns, they play a crucial role in reducing waste by optimizing the injection moulding process. This includes minimizing plastic material waste and ensuring efficient energy usage during manufacturing.

Moreover, these manufacturers are continually evolving to keep pace with technological advancements. They invest in cutting-edge machinery and software to streamline their processes, reduce lead times, and enhance the quality of their moulds. This commitment to innovation ensures that home appliances not only meet but often exceed our expectations.

The partnership between home appliance manufacturers and plastic injection mould manufacturers is a symbiotic one. It's a relationship built on collaboration and trust. Designers and engineers work closely with mould manufacturers to translate their ideas into tangible products. The manufacturers, in turn, provide valuable insights into the feasibility of these designs, suggesting improvements when necessary.

As consumers, we often take for granted the seamless operation of our home appliances. We rarely pause to consider the meticulous craftsmanship that goes into their creation. Plastic injection mould manufacturers are the unsung heroes who make our lives more comfortable, efficient, and enjoyable. They bridge the gap between innovation and reality, transforming concepts into tangible, everyday solutions.

In conclusion, home appliance plastic injection mould manufacturers are the artisans of modern living. Their dedication to precision, quality, sustainability, and innovation ensures that our appliances are not only functional but also elegant and eco-friendly. They are the silent force that shapes the future of home appliances, making our daily lives more convenient and enjoyable, one mould at a time.